Features

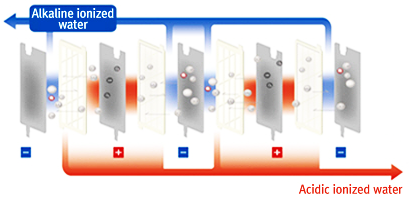

The electrolysis system is the core part of water ionizer, and thus, its quality, component materials, design, know-how etc., affect the performance of electrolysis process and the effectiveness of ionized water generated very much.

The most crucial factor is the material of electrodes, as this is the major component in electrolyzing the water molecules into ions. However, electrode itself will be corroded and dissolves into water during electrolysis. Hence, the water ionizer cannot perform electrolysis any more once the electrodes are totally corroded. Additionally, the water is contaminated by dissolved electrode ions as well.

BionTech adopts platinum-coated titanium to make electrodes. In the core of electrodes, PURE TITANIUM (not titanium alloy) is used due to its high conductivity, corrosion resistance features. In order to further protect the core part, 99.99% PLATINUM (almost pure, not platinum alloy) is coated on the surface of the titanium core by using special coating method “DSE in 6μm”. With attributes like high conductivity, durability and stability even in high temperature, platinum coating benefits electrodes in extending its lifespan and efficiency.

Distinctive Features of BionTech's Eletrolysis System

- Adoption of pure titanium (Unalloyed Ti "Pure" 50A)

- 99.99% platinum (Pt) coating: Dual-Stage Electroplating (DSE) 6μm Method

- Embossing effect achieved by sanding the surface of the electrodes

- High stability and corrosion resistance

- Extra large surface area of electrodes

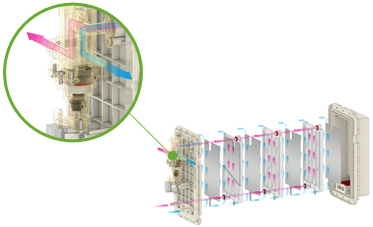

- 7 Layers of electrodes

Total surface area of electrodes is another critical concern. Electrolysis mainly occurs in the surface of electrodes, and hence, larger surface area of electrodes, electrolysis process is more effective because more energy and electrons can be released during the process. Therefore, more activated hydrogen can be generated and the ORP value can be lower.

BionTech has extra large surface area of single layer electrode. The model “Black Diamond” has 7 layers, so the electrolysis performance can be maximized.

The core part of the Electrolysis Ionized Water System is the electrolysis chamber. By using a cutting edge material - "platinum-coated Titanium", which is produced by the new and unique technology of BionTech, electrolysis can be performed much effectively.

During the eletrolysis process, the positive hydrogen ion (H+) gains energy and electron in cathode side to become either activated hydrogen / hydrogen atom (H) or hydrogen gas (H2). Another product, hydroxyl ions (OH-), is produced as well. OH- is a strong reducing agent with negative ORP value. Lower ORP value, it has higher reducing power. BionTech Ionizer is able to make -500mV* (Super Low Level) ORP alkaline water.

*This is the value performed in manufacturer. The actual ORP value may be different due to different water inlet quality.

Automatic self-cleaning is performed at every 10 litres of water consumption to maintain the electrolysis function. The process lasts for 30 seconds and is performed automatically once the machine is switched off. Then it interchanges the electric connection of cathodes and anodes. The cathodes become anodes and vice versa. It removes the minerals such as calcium, magnesium, etc., which attached on the electrodes effectively.

When self-cleaning is completed, detached materials dissolve in the water and are drained off by the automatic drainage process. Therefore, the electrodes and the electrolysis chamber can be cleaned and the electrolysis system can have longer lifespan.

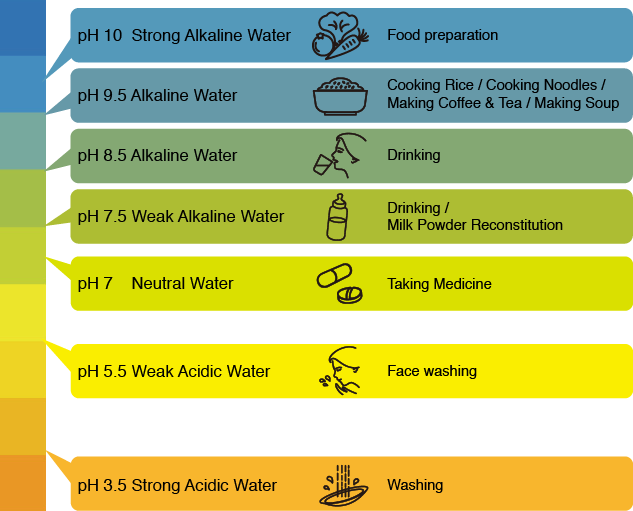

BionTech Ionizer is able to supply acidic / alkaline water with 6 steps of pH value and neutral (pH 7) water. Alkaline ionized water has 4 pH levels selection (pH 7.5, pH 8.5, pH 9.5 & pH 10) while Acidic ionized water has 2 (pH 3.5 & pH 5.5). Different pH level of ionized water has various applications. For instance, acidic water with pH 5.5 and pH 3.5 can be used for face washing and general washing respectively. Similarly, alkaline water with pH 7.5 and 8.5 is suitable for drinking directly, and pH 9.5 is suitable for cooking. Details can be referred to the diagram beside and the page "Applications".

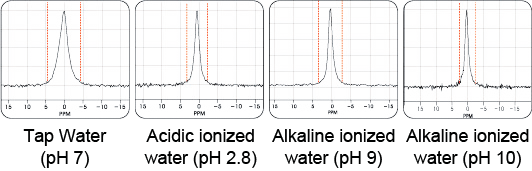

| Type | Water Molecule Group |

|---|---|

| Neutral Tap Water (pH 7) | 104.8479Hz |

| Acidic Ionized Water (pH 2.8) | 55.2724Hz |

| Alkaline Ionized Water (pH 9) | 50.3593Hz |

| Alkaline Ionized Water (pH 10) | 50.076Hz |

According to the diagram beside, the cluster size of water after the electrolysis process performed by BionTech water ionizer is almost half of the untreated tap water no matter it is acidic or alkaline ionized water. Some large water molecular groups (clusters) gain energy from electrolysis process to break into several smaller water molecular groups. Therefore, the average cluster size of water is smaller.

Ultra Fine Filtration

Ultra Fine Filtration

Equipped with UF membrane, BionTech’s filter can remove substances as small as “0.1μm” and even bacteria (0.2μm - 1μm in general). In addition, it has 7 layers of filtration such as the silver-coated activated carbon, which is the core material of the filter. It enhances the capability of sterilization and suppress bacterial growth.

Besides, other impurities such as lead, mercury, VOC, chlorine, etc. can be removed as well. Hence, the purified water is safe to drink directly.

Filter Change Remind

Filter Change Remind

The flow of water is accurately detected by the flow detection sensor system, and the filter remained lifespan is displayed on the LCD. Filter should be replaced after 3,000L of water purified and the ionizer notifies you by voice and message on LCD. A.I. Self-Diagnosis

A.I. Self-Diagnosis

The self-diagnosis system analyses any failure operation and show the error code on LCD. Repairing becomes easy and convenience. Furthermore, this safety system is able to cut the power automatically in case excessive current detected. Status Announcement

Status Announcement

BionTech water ionizer announces the operation status by voice for any water pH selection changes. Users can be reminded which acidic / alkaline water is in use. If any acidic water mode is selected, music will be played after the status announcement to remind users that the water is not suitable for drinking. When auto-cleaning is processing, there is voice warning as well.Certificates

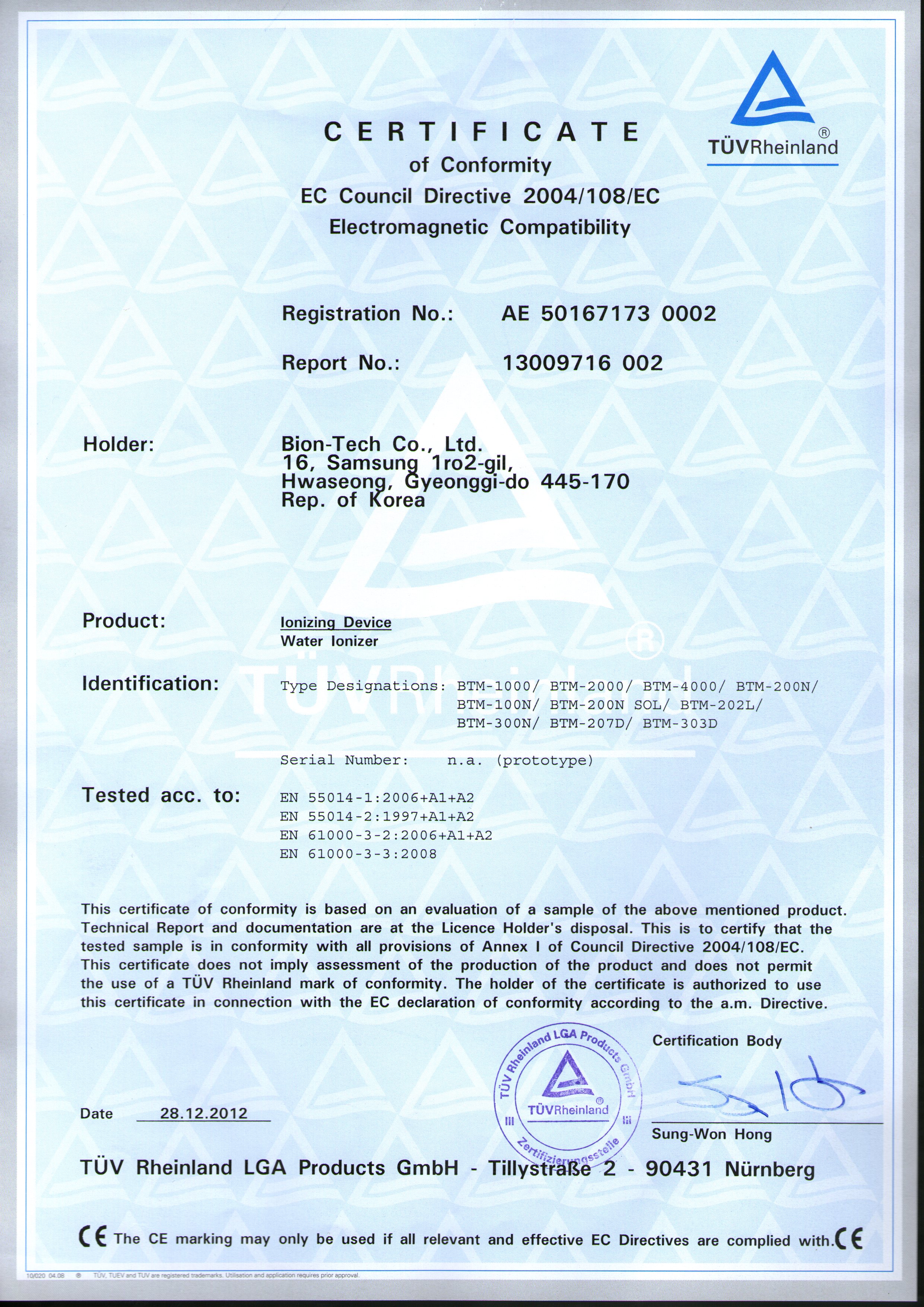

EMC Certificate (CE)

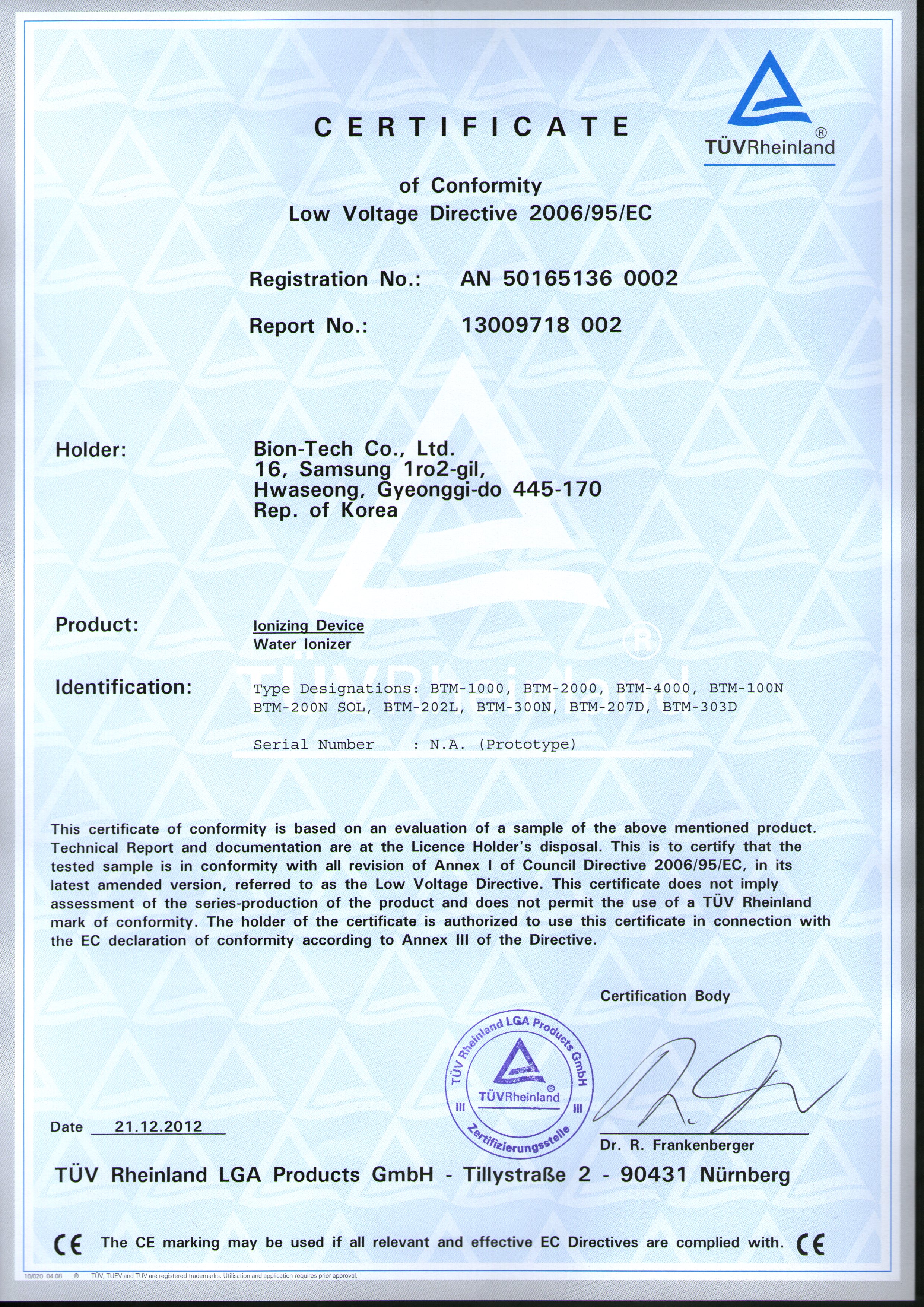

LVD Certificate (CE)

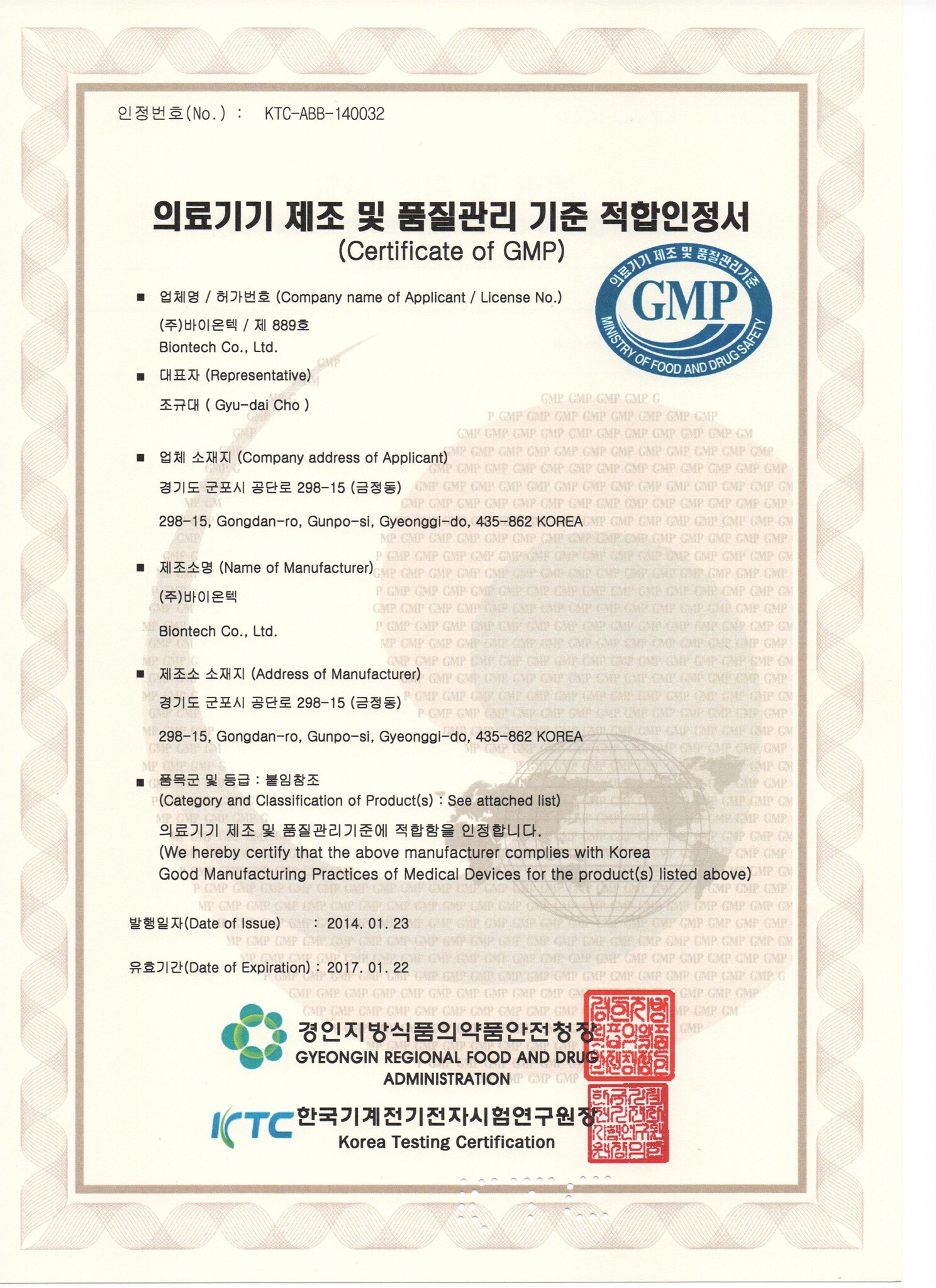

GMP Certificate

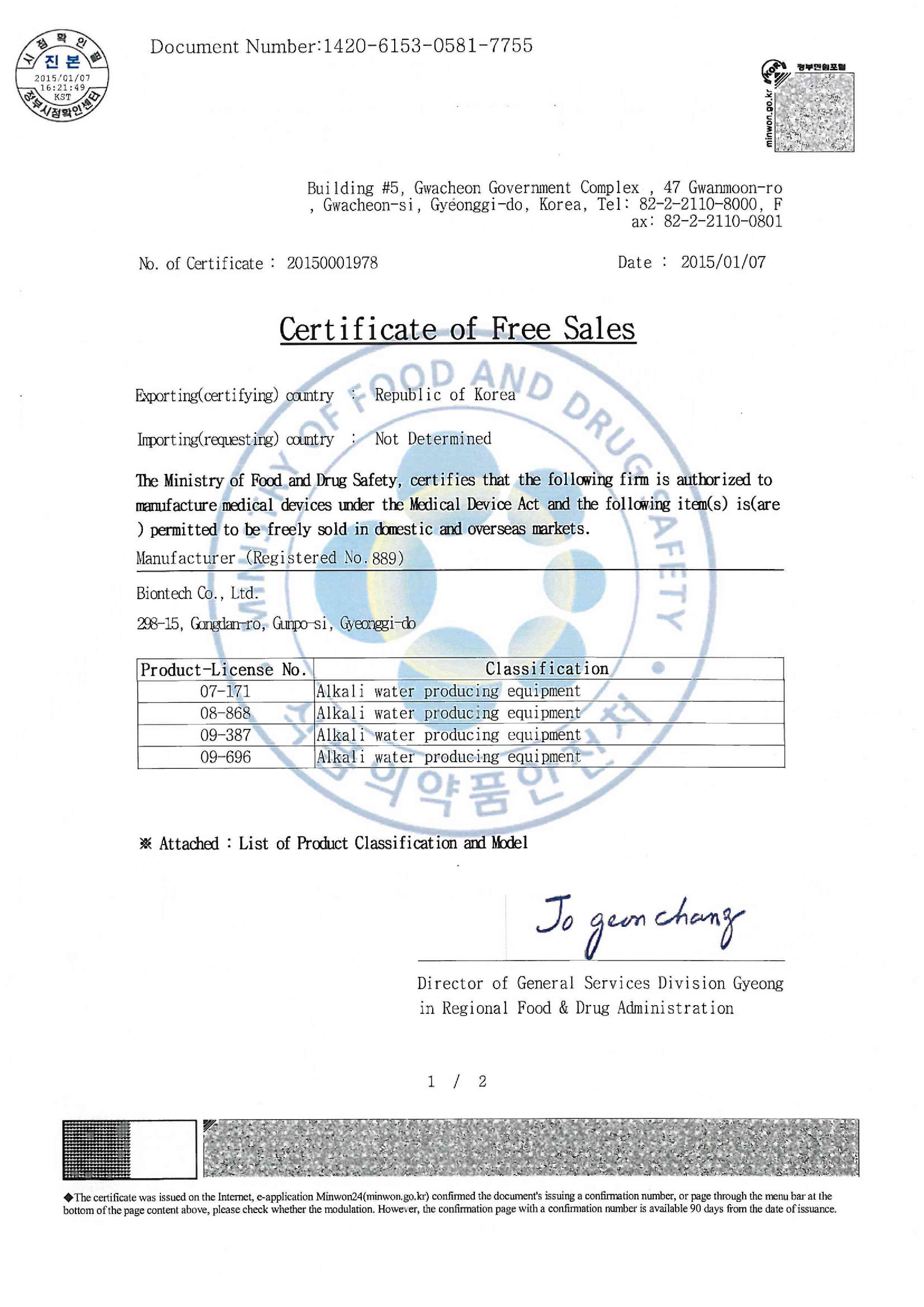

KFDA Certificate

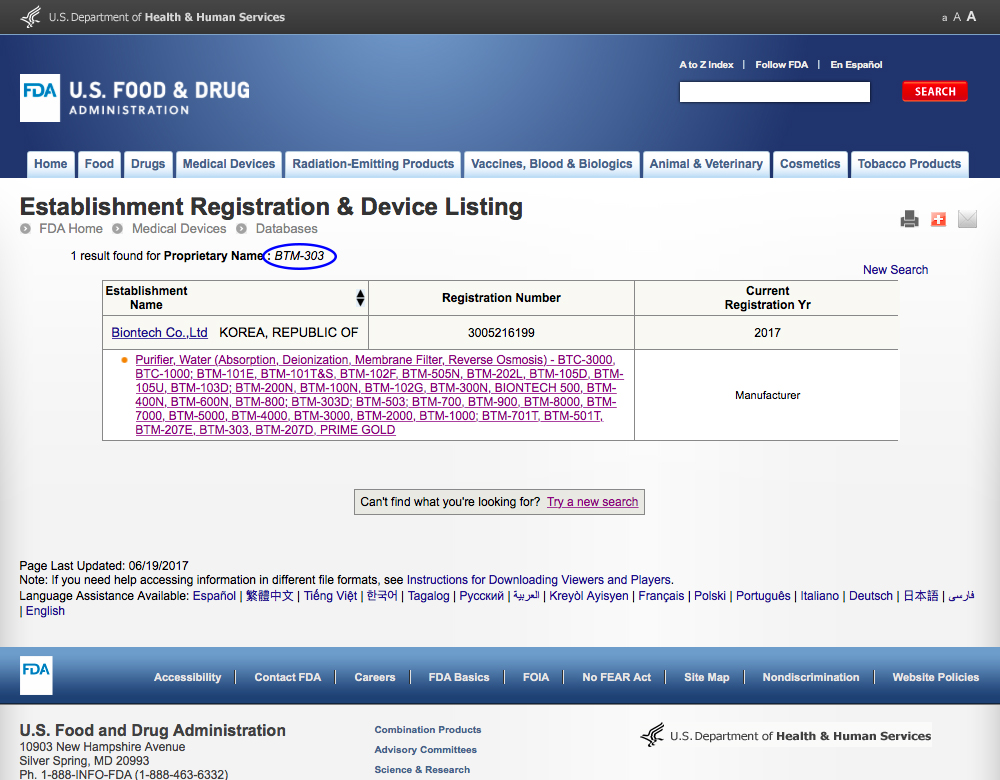

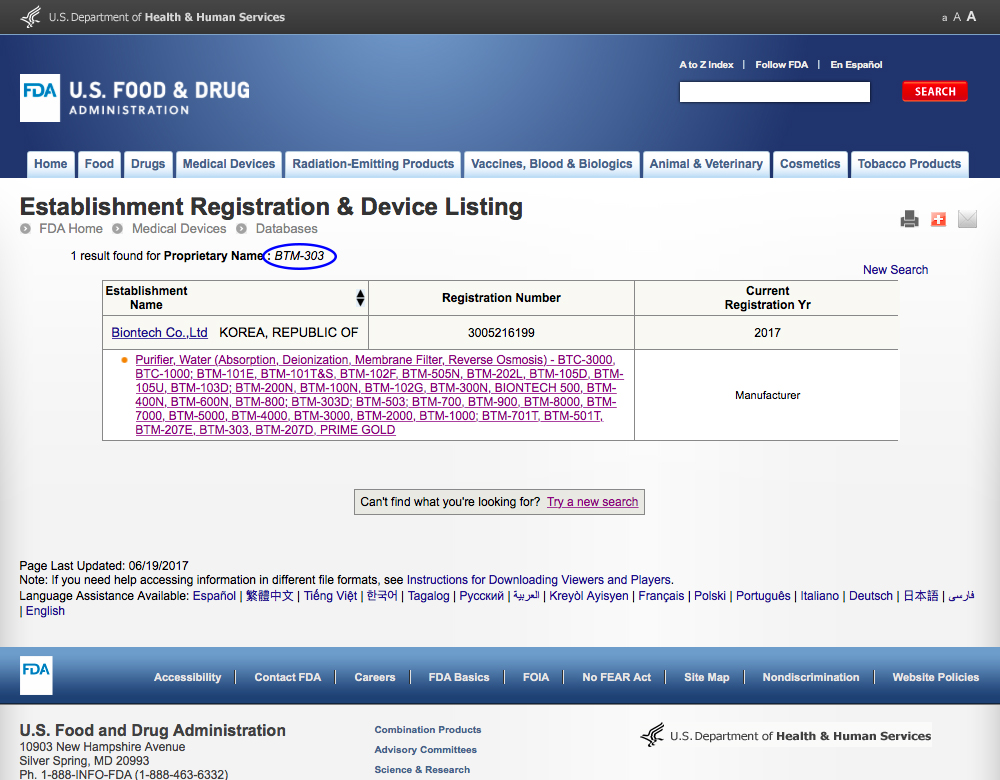

FDA

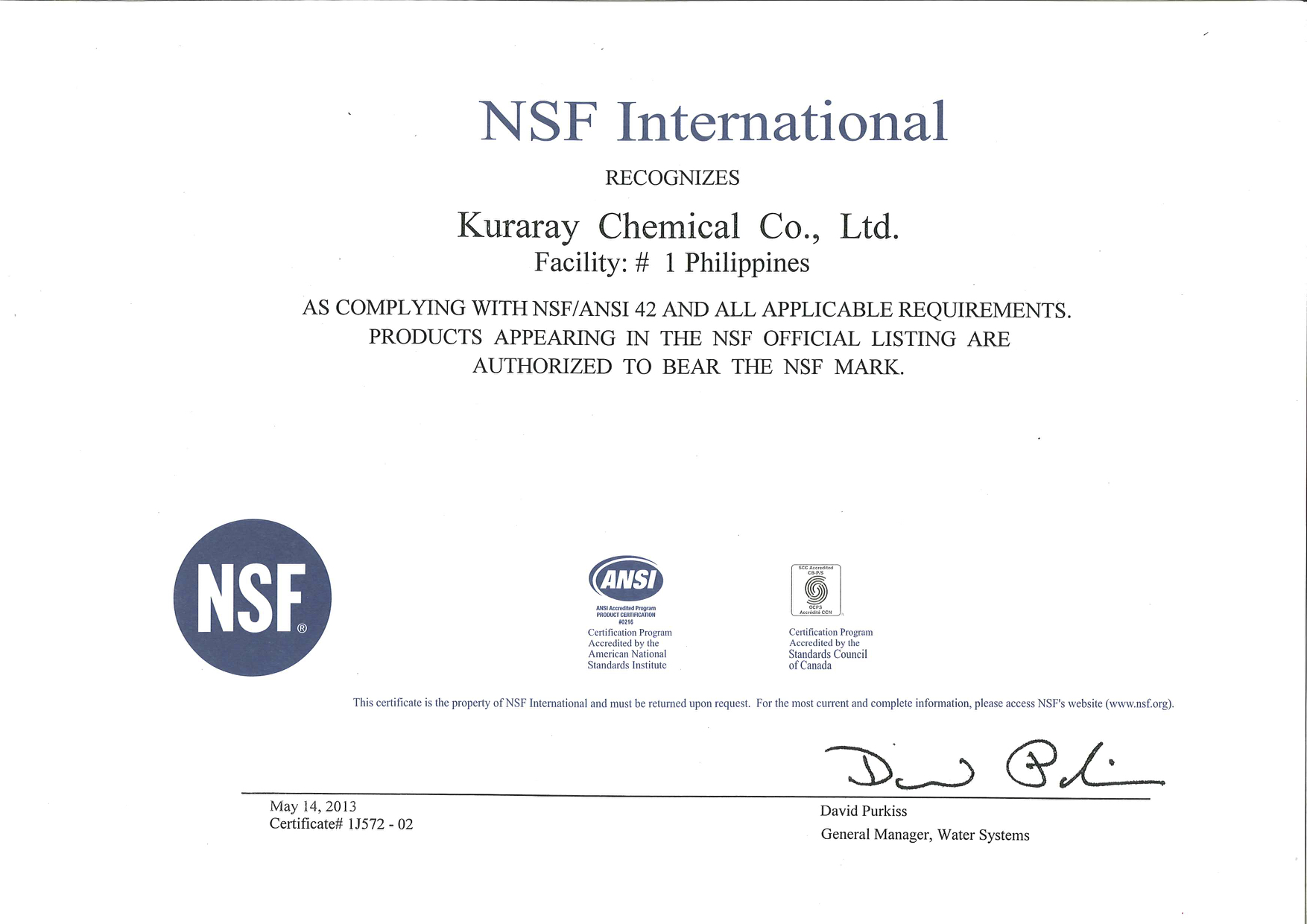

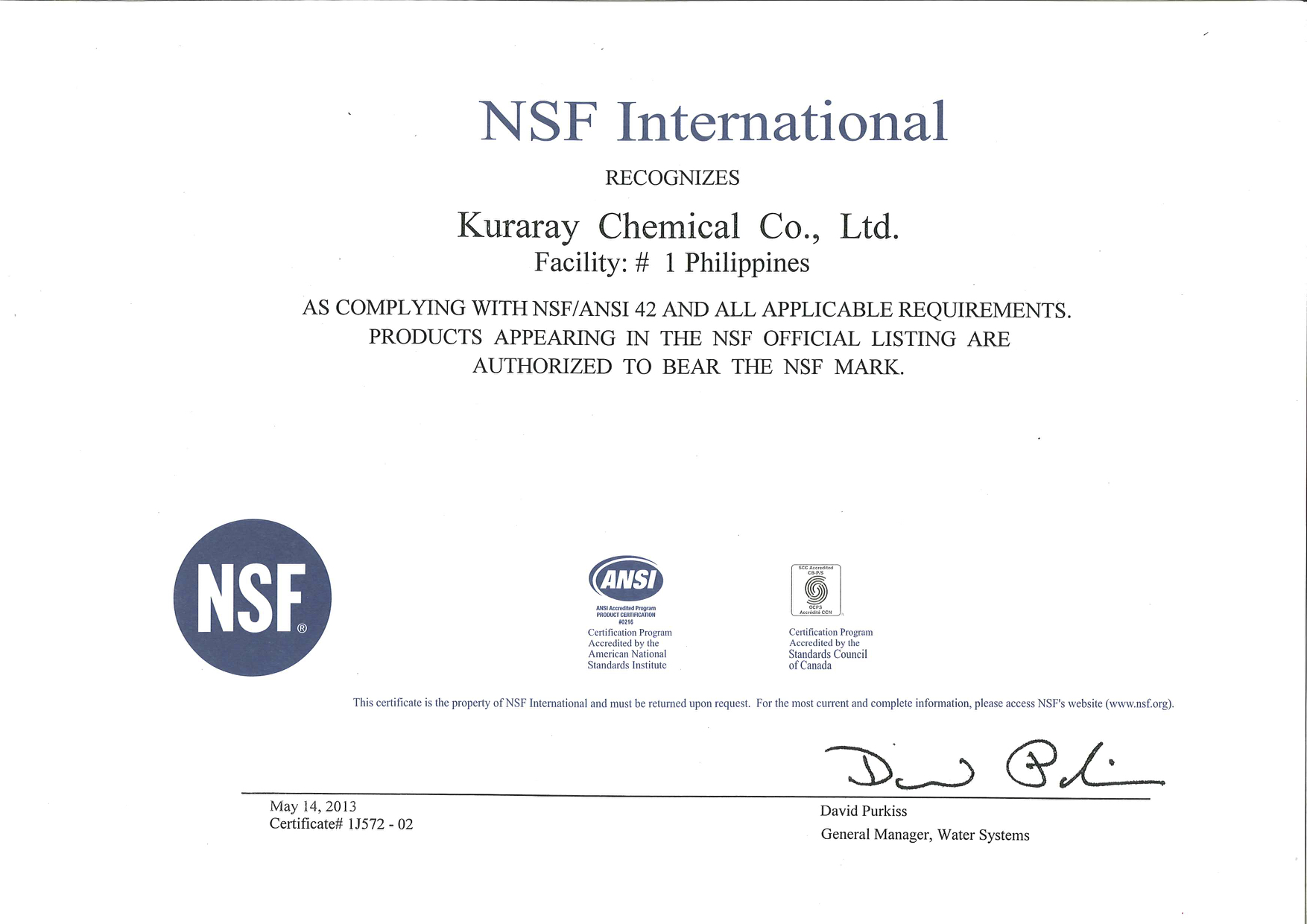

NSF 42 Certificate

Specification

Basic Information

- Dimension: 280(W) x 375(H) x 155(D) mm

- Weight: ~6 KG

- Power Supply: 220V - 230V, 50Hz - 60Hz

- Power Consumption: 150W - 200W

- Suitable Water Pressure: 70 ~ 500 kPa / 0.7 - 5.0 kgf/cm2

- Suitable Working Temperature: 5 - 30oC / 41 - 86oF

- Protection Devices: 2 Built-in Temperature Sensor (Auto-Reset)

- Touch Panel

- LCD Display

- Operation status announcement

- Suitable for Wall-Mount & Table-Top

- 180o Free Adjustment Faucet

Electrolysis System

- Continous Electroysis

- Normal: 1.5 L / Min (+ 0.5 L) (At 196.1 kPa / 2.0 kgf/cm2)

- Max.: 3.3 L / Min (At 323.6 kPa / 3.3 kgf/cm2)

- 4 Steps of Alkaline Ionized Water (pH 7.5 / 8.5 / 9.5 / 10)

- 2 Steps of Acidic Ionized Water (pH 3.5 / 5.5)

- Neutral Purified Water (pH 7)

- Auto-Cleaning (Cleaning Time ~ 30 Sec / 0.8 L Drainage Volume)

- 7 Layered Platinum-Coated Titanium Electrodes (Pure Titanium and Platinum Used)

Certification & Registration

- KFDA Manufacturing Registered No.: 889

- Product License of Medical Device Listing: 09-387

- Class 2, Type B Equipment

- CE / FDA Class 1 / GMP / KFDA

Filtration System

- 3000 L (5 - 6 Months / Assuming daily consumption 20 L or 5.3 Gallon)

- Filter Remaining Lifespan Counter

- Filter Replacement Reminder

- Sealed Packaging, and Easy to change

- NSF Certified Materials (Woven Fabric, UF Membrane, Silver-Coated Granular Activated Carbon, etc.)

Usage